6.5dragracer

Chevy Man...

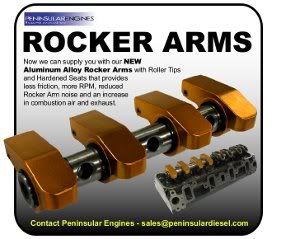

i know there was a guy who built a set of roller rockers for the 6.5 and he said that he wouldn't build any more but i was wondering how hard it would be to make a set and how much would it cost me????

and what part i would need???

and what part i would need???